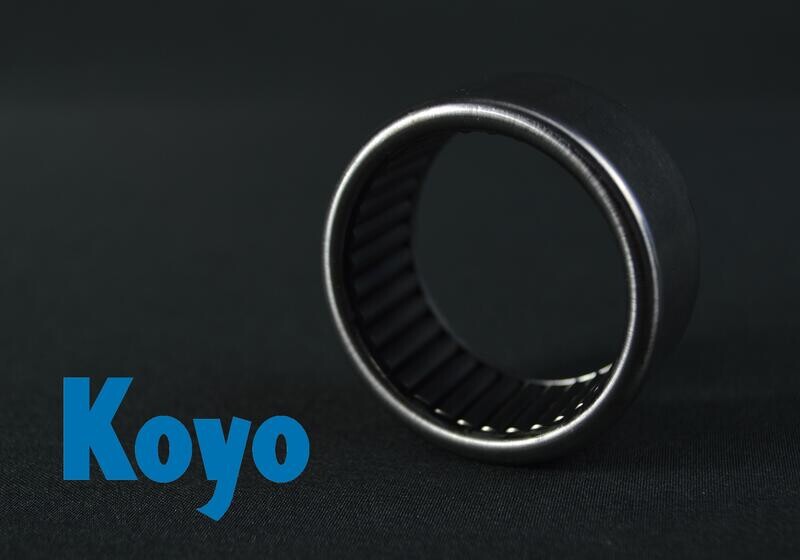

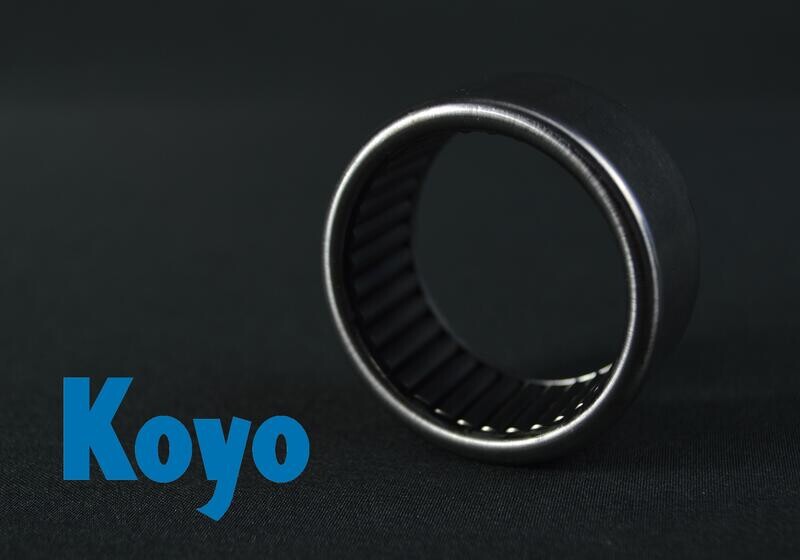

Shell Type Needle Roller Bearings

Shell Type Needle Roller Bearings: High-Performance Bearings for Compact Applications

Shell type needle roller bearings are compact and lightweight bearings designed to handle high radial loads efficiently in applications where space is limited. These bearings are ideal for industries that require both strength and precision without adding significant bulk to machinery. At Tapered Roller Bearings, we offer a wide range of these bearings designed to meet the needs of industries like automotive, industrial machinery, and more.

What Are Shell Type Needle Roller Bearings?

These bearings feature a unique, thin-walled outer shell with high-density needle rollers arranged radially inside. Unlike traditional roller bearings, these needle roller bearings use long, thin rollers, allowing them to maintain a compact design while supporting high radial loads. The thin outer shell reduces the bearing’s profile, enabling it to fit into applications with limited radial space.

These bearings can be used directly on the shaft, eliminating the need for an inner ring in some cases, which further reduces space requirements. Made from high-quality materials, shell type needle roller bearings offer reliable performance in demanding applications.

Benefits of Shell Type Needle Roller Bearings

- Space-Efficient Design Shell type needle roller bearings are designed with a thin outer shell, making them ideal for applications where space is at a premium. This space efficiency makes it easy to incorporate these bearings into various compact applications, such as gearboxes and automotive components, without compromising load capacity.

- High Load-Bearing Capacity Despite their small size, shell type needle roller bearings can handle substantial radial loads. Their high load-bearing capacity makes them suitable for applications subjected to heavy radial forces, ensuring reliable performance even in demanding environments.

- Lightweight Construction These bearings are lightweight, thanks to the streamlined design and absence of an inner ring in certain applications. The reduction in weight is beneficial in applications where minimizing weight is critical, such as in automotive and aerospace industries, contributing to improved energy efficiency.

- Reduced Friction and Heat Generation These bearings are designed to minimize friction, which results in less heat generation during operation. This efficiency reduces wear, extending the lifespan of the bearing and minimizing the need for maintenance.

- Easy Installation and Versatility With their simple design, shell type needle roller bearings are easy to install and can be applied in a variety of configurations, either with or without an inner ring. Their versatility makes them suitable for numerous industrial applications that require high load capacity in limited space.

- Cost-Effective Solution Given their robust design and high load capacity, shell type needle roller bearings offer a cost-effective solution for applications that require durable and efficient bearings. Their longevity and minimal maintenance needs translate into reduced operating costs over time.

Industries and Applications for Shell Type Needle Roller Bearings

These bearings are used across various industries due to their compact design and load-handling capabilities. Here’s a look at some common applications and sectors where these bearings are highly effective:

- Automotive Industry In the automotive sector, these bearings are commonly used in transmissions, steering mechanisms, and differential systems. Their ability to withstand high radial loads in a compact form factor makes them suitable for use in these critical components, where both performance and space are essential. Additionally, the lightweight design contributes to fuel efficiency and vehicle performance.

- Industrial Machinery Industrial equipment often requires robust bearings that can manage high radial loads in compact spaces. Shell type needle roller bearings are ideal for applications in industrial machinery, such as conveyors, pumps, and gearboxes. Their load-handling capacity and durability enhance machinery reliability, making them an asset in environments where equipment operates continuously.

- Agricultural Equipment In agricultural machinery, space is limited, but load demands are high, especially in equipment like tractors, combines, and harvesters. These bearings are commonly used in such applications, providing reliable performance and withstanding challenging conditions found in agricultural settings.

- Power Tools and Handheld Equipment For power tools and other handheld equipment, the lightweight and compact nature of shell type needle roller bearings makes them ideal. These bearings help maintain the tool’s performance without adding unnecessary weight, ensuring ease of use and efficiency in demanding applications.

- Aerospace Industry The aerospace industry values components that offer high performance while keeping weight and size to a minimum. Shell type needle roller bearings meet these criteria, making them suitable for various aerospace applications, such as control systems and auxiliary equipment, where space and weight restrictions are critical.

- Construction and Off-Highway Equipment Heavy-duty construction machinery and off-highway equipment require durable bearings that can withstand heavy loads and challenging environments. These bearings provide a compact, robust solution for hydraulic pumps, transmissions, and other vital components in construction equipment.

Why Choose Shell Type Needle Roller Bearings?

These bearings offer an excellent combination of compactness, strength, and reliability, making them a versatile solution for various industries. Here are some reasons why these bearings are a preferred choice:

- Compact Form Factor: Their thin-walled design allows them to fit into applications with limited radial space, offering an ideal solution for compact machinery and devices.

- Durability and Load Capacity: These bearings are constructed to handle heavy radial loads efficiently, ensuring long-lasting performance and reducing the risk of mechanical failure.

- Versatile Application: Suitable for multiple configurations, shell type needle roller bearings provide versatility across industries, meeting specific application requirements with ease.

- Low Maintenance: With minimal friction and heat generation, these bearings have a longer lifespan and lower maintenance demands, which contributes to reduced downtime.

Why Purchase Shell Type Needle Roller Bearings from Tapered Roller Bearings?

At Tapered Roller Bearings, we specialize in offering high-quality bearings suited for diverse industrial applications. Our bearings are sourced from trusted manufacturers such as IKO, KOYO JTEKT and NTN known for their quality and performance. With a wide inventory of bearing options, we are equipped to meet the specific requirements of industries needing reliable, compact bearing solutions.

Our experienced team is available to assist in selecting the best bearing for your application, ensuring both performance and cost-efficiency. We also prioritize fast delivery to minimize downtime and support the efficient operation of your equipment.

Conclusion

Shell type needle roller bearings are a powerful and efficient solution for industries that require high load capacity in a compact, space-efficient design. With applications ranging from automotive and aerospace to industrial machinery and power tools, these bearings offer durability, reliability, and ease of use.

Visit Tapered Roller Bearings to explore our extensive selection of shell type needle roller bearings and find the ideal fit for your application. Contact us today to learn more about how we can support your bearing needs.