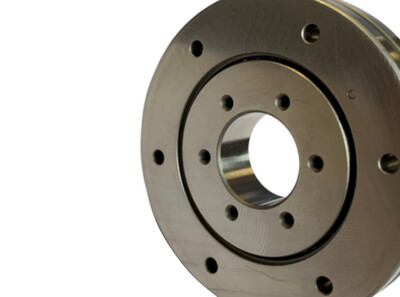

Crossed Roller Bearings: IKO Available

Crossed roller bearings are specialized bearings that offer superior rigidity, precision, and compactness. These bearings are uniquely designed with rollers positioned at right angles to each other in a crisscross pattern, allowing them to handle radial, axial, and moment loads simultaneously. With their exceptional load-bearing capabilities and compact design, crossed roller bearings are used in applications that demand high precision, stability, and space-saving configurations. Industries such as robotics, medical equipment, aerospace, and machine tools rely on crossed roller bearings to provide accurate and reliable performance.

What Are Crossed Roller Bearings?

These bearings are composed of an inner ring, an outer ring, and rollers arranged at 90-degree angles. This crisscross arrangement of rollers between the rings enables the bearing to handle complex loads in a single bearing setup, accommodating radial, axial, and tilting moment loads. The unique design eliminates the need for multiple bearings, making crossed roller bearings an ideal choice for applications where space is limited and high rigidity is essential.

Crossed roller bearings come in various types and configurations to suit different applications. Some models include split inner rings or outer rings, which aid in smooth assembly and maintenance. They can also be customized with seals for contamination protection and corrosion resistance to enhance durability in specific environments.

Key Benefits of Crossed Roller Bearings

- High Load-Bearing Capacity in All Directions: Due to their unique design, these bearings can support loads from all directions, including radial, axial, and moment loads. This three-way load-bearing capability allows them to handle complex applications where standard bearings might fall short.

- Compact and Space-Saving Design: Crossed roller bearings combine the functions of multiple bearings into one, reducing the space required for installation. This compact design is ideal for applications that demand precision within a limited footprint, such as robotic arms, medical imaging equipment, and machine tools.

- Exceptional Rigidity and Precision: These bearings offer high rigidity due to the crisscross arrangement of rollers, which ensures uniform load distribution across the bearing. This rigidity is essential in high-precision applications where stability and accurate positioning are critical, such as CNC machines and measuring instruments.

- Smooth Rotation and Reduced Friction: The design of crossed roller bearings minimizes friction, leading to smoother rotation and less wear over time. The rollers’ perpendicular orientation reduces sliding friction, enhancing efficiency and prolonging the life of the bearing.

- Reduced Need for Multiple Bearings: With their ability to handle multi-directional loads, crossed roller bearings reduce the need for additional bearings. This simplifies assembly, reduces weight, and cuts down on the cost and complexity of equipment design.

- Enhanced Durability in Demanding Environments: Crossed roller bearings can be manufactured with corrosion-resistant materials and protective seals, making them suitable for environments where contamination, moisture, or debris might affect performance. The added durability ensures reliable performance in diverse applications and extends the bearing’s operational life.

- Multiple Types: Crossed roller bearings are available in many different types including a basic standard design, slim, super slim, high rigidity, and mounting holed.

Common Applications and Industries for Crossed Roller Bearings

Crossed roller bearings are used in industries that require high precision, rigidity, and compact bearing solutions. Here are some of the primary applications where crossed roller bearings excel:

- Robotics and Automation: Robotics applications demand precise and stable movement, especially in articulated robotic arms, joint mechanisms, and end effectors. Crossed roller bearings provide the rigidity and load-bearing capacity required for accurate positioning, enabling robots to operate with the precision needed in automation tasks.

- Medical Equipment: In the medical field, crossed roller bearings are commonly used in imaging equipment like MRI and CT scanners, where stability, smooth rotation, and compactness are essential. They help provide accurate motion control, enhancing the reliability of imaging and diagnostic procedures.

- Aerospace Industry: Aerospace applications often involve complex load scenarios, where lightweight and highly rigid components are critical. Crossed roller bearings are used in aircraft instruments, navigation systems, and landing gear, providing stability and precision in a compact form factor, which is essential for high-performance aerospace equipment.

- Machine Tools: Precision and rigidity are critical in machine tools, including CNC machines, milling machines, and lathes. Crossed roller bearings support these machines by ensuring precise spindle rotation and smooth operation, leading to improved accuracy and productivity in machining processes.

- Semiconductor Manufacturing: Semiconductor manufacturing equipment, such as wafer handling and alignment systems, requires high-precision motion control to maintain accuracy during the production process. Crossed roller bearings deliver the stability and compact design necessary for accurate movement in this high-tech industry.

- Optical and Measurement Instruments: In optical devices and precision measuring instruments, crossed roller bearings are used for their high rigidity and accuracy. Equipment like laser measurement tools, spectrometers, and telescopes benefit from the stability and smooth rotation offered by crossed roller bearings.

- Military and Defense Applications: Military applications often demand robust, compact, and precise components. Crossed roller bearings are used in military-grade radar systems, gyroscopes, and targeting systems, where their high load-bearing capacity and durability enhance reliability in mission-critical operations.

Crossed Roller Bearings at [Your Company Name]

At Tapered Roller Bearings, we specialize in providing high-quality crossed roller bearings designed to meet the demands of high-precision applications. Our range includes various configurations, from compact models for space-constrained environments to sealed designs for contamination protection. With bearings sourced from trusted manufacturers, we ensure durability, precision, and reliability across all our products. Whether you are designing robotic equipment, medical machinery, or advanced machine tools, our experts are here to help you find the ideal crossed roller bearing for your application.

Conclusion

Crossed roller bearings offer a unique combination of high rigidity, multi-directional load capacity, and compact design, making them indispensable in industries where precision and stability are critical. From robotics and aerospace to medical equipment and semiconductor manufacturing, these bearings ensure reliable performance, even in complex load scenarios. With the benefits of reduced friction, high load-bearing capacity, and minimal maintenance requirements, crossed roller bearings deliver long-lasting value and operational efficiency. At Tapered Roller Bearings, we are proud to provide a comprehensive selection of crossed roller bearings tailored to meet your industry’s most demanding requirements. Contact us today to learn more about our crossed roller bearing solutions and how they can enhance your equipment’s performance and reliability.