Belts - PIX

Industrial belts are an essential component of modern machinery and equipment, designed to transmit power, motion, and torque from one part of a system to another. These belts are made from high-quality materials such as rubber, polyester, polyurethane, or metal, and are engineered to perform reliably in demanding industrial environments.

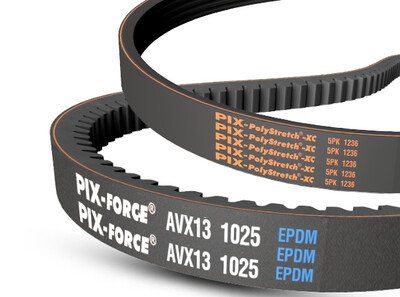

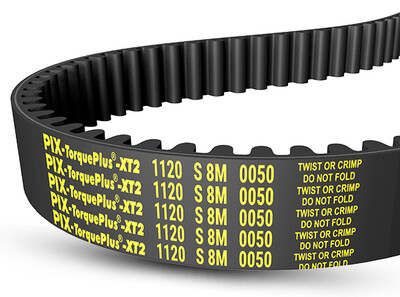

Industrial belts come in a wide variety of types, including v-belts, timing belts, lawn mower belts, hexagonal belts, flat belts, ribbed belts, automotive belts and specialty belts, each with unique features and applications. V-belts are commonly used in power transmission systems and feature a trapezoidal cross-section that provides high frictional grip and allows for efficient power transfer. Timing belts have toothed profiles that enable precise motion control in applications such as conveyor systems, printing presses, and automotive engines. Flat belts are versatile and used in a wide range of applications, while ribbed belts have grooved surfaces that offer enhanced grip and flexibility for high-speed operations. Specialty belts are designed for specific uses, such as for heavy-duty applications or in industries with unique requirements like food processing or pharmaceuticals.

Industrial belts are known for their durability, strength, and resistance to wear, heat, chemicals, and abrasion. They are capable of transmitting high levels of power and torque while maintaining consistent performance over long periods of operation, minimizing downtime and improving productivity in industrial processes. These belts are also designed to be easy to install, adjust, and maintain, making them a cost-effective choice for many industries.

In addition to their functional attributes, industrial belts are often designed with safety features such as anti-slip coatings, static dissipation properties, and noise reduction capabilities to ensure worker safety and protect the integrity of the machinery. They are also engineered to operate with minimal vibration and noise, contributing to a safer and more comfortable work environment.

Overall, industrial belts play a crucial role in powering the machinery and equipment that drive various industries, enabling efficient and reliable operation in a wide range of applications. Their durability, versatility, and performance make them an essential component in modern industrial systems, facilitating the smooth and efficient operation of industrial processes around the world.

There are several benefits of using industrial belts in various industrial applications:

1). Power Transmission: Industrial belts are designed to transmit power from one part of a system to another, allowing for efficient transfer of energy in machinery and equipment. They can transmit high levels of power and torque, enabling the operation of heavy machinery and high-speed processes.

2). Motion Control: Certain types of industrial belts, such as timing belts, provide precise motion control, allowing for accurate positioning and synchronization of mechanical components. This is crucial in applications such as conveyor systems, printing presses, and robotics, where precise movement is required for optimal performance.

3). Durability and Reliability: Industrial belts are made from high-quality materials and are engineered to withstand demanding industrial environments, including exposure to heat, chemicals, abrasion, and wear. They are designed for long-lasting performance, reducing downtime and maintenance costs.

4). Versatility: Industrial belts come in various types, sizes, and configurations, making them suitable for a wide range of applications across different industries. They can be customized to meet specific requirements, such as different lengths, widths, and profiles, making them highly versatile and adaptable to different machinery and equipment.

5). Easy Installation and Maintenance: Industrial belts are typically easy to install and adjust, allowing for quick replacement or maintenance. This helps reduce downtime and increases productivity. They also require minimal lubrication or maintenance, resulting in cost-effective operation.

6). Safety: Industrial belts are often designed with safety features such as anti-slip coatings, static dissipation properties, and noise reduction capabilities, contributing to a safer work environment. They can also reduce vibration and noise levels, minimizing operator fatigue and improving overall safety.

7). Cost-Effective: Industrial belts are generally cost-effective compared to other methods of power transmission, such as gears or chains. They require lower initial costs, are easy to replace, and typically have longer service life, resulting in lower maintenance and operational costs over time.

8). Energy Efficient: Industrial belts have high efficiency in power transmission, which can result in energy savings compared to other methods. They can operate with minimal energy loss, contributing to improved overall energy efficiency in industrial processes.

In summary, industrial belts offer numerous benefits, including efficient power transmission, precise motion control, durability, versatility, ease of installation and maintenance, safety features, cost-effectiveness, and energy efficiency. They are a critical component in modern industrial systems, contributing to reliable and efficient operation in a wide range of applications.